Crown can complete all steps of biodiesel preparation, testing and production in our Global Innovation Center.

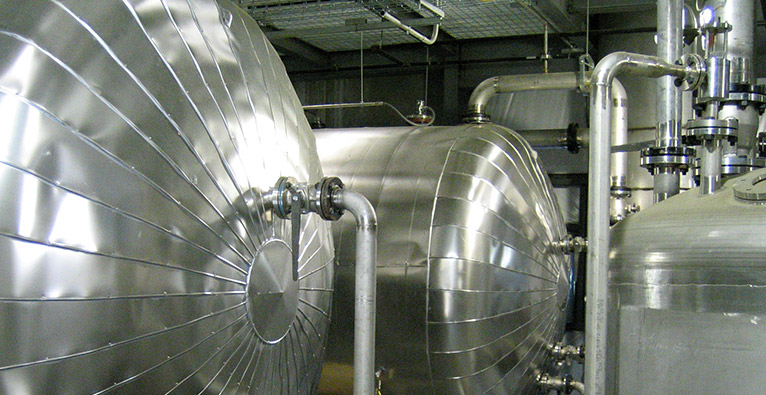

The Crown biodiesel process uses a multistep transesterification reaction followed by neutralizing and washing steps. The multistep transesterification reaction converts nearly 100% of the triglycerides in the oil or fat to biodiesel (methyl ester). The methyl ester is then stripped to remove the water and methanol. The final step is to chill and filter the methyl ester in order to remove impurities that form at low temperatures. This filtered methyl ester now meets the definition of biodiesel and can be used as a fuel, heating oil or in other applications.

The glycerin byproduct separated from the methyl ester is further processed by removing methanol and some of the water so that it that can easily be refined in a glycerin refining plant.

The excess methanol from both the methyl ester and glycerin fractions is recovered and reused for environmental and economic reasons.

Crown Advantages

- All equipment is typical for an industrial process and not simply a collection of tanks and plastic tubing

- Using a proven design ensures maximum equipment reliability and product quality

- Centrifuges are not used in the process, eliminating expensive maintenance issues

- Gravity separation of methyl ester from other product phases eliminates maintenance headaches and the high cost of high-speed rotating equipment

- Specifying a high-quality feedstock ensures that process upsets are minimized because feedstock variations are taken care of in pretreatment, minimizing the total processing cost

- Wash water is not discharged as a waste stream

Crown Design Features

- Straightforward process standard to the biodiesel industry

- Catalyst used is standard and readily available, no licensing needed

- Flexible design allows processing of one or multiple types of pretreated feedstock with the same equipment

- Feedstock specifications to the plant are typical for a partially refined edible oil to ensure the transesterification plant will be able to process any kind of oil or fat into biodiesel

- Long reaction and separation time ensures maximum efficiency with a high product conversion

- Crude glycerin byproduct from the process is the same or better quality than the crude glycerin typically processed in existing glycerin refining equipment at soap plants

- Wash water used for cleaning the methyl ester is reused in the glycerin cleanup section and combined with the crude glycerin